How clarity, respect, and one simple agreement unlocked engagement and protected results.

Read MoreI visited a consumer goods factory in Pennsylvania. They were profitable, but concerned their ability to service customer orders was deteriorating. I met with plant leadership and took a Gemba walk through the distribution center.

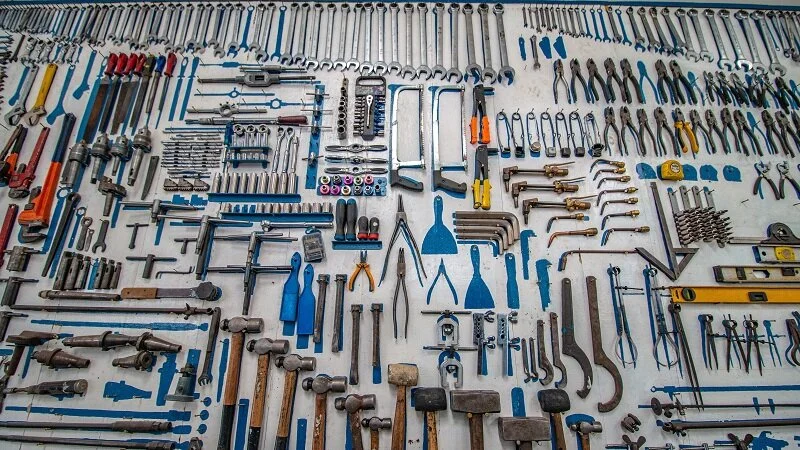

Read MoreThe Pilot Plant at Armstrong World Industries, a global ceiling tile manufacturer, has tons of operating equipment designed to allow technicians, engineers, and scientists to try out their ideas and experiment in their efforts to create new processes and products. One of the areas in the Pilot Plant that gets the most use is the wood shop. Containing over 50 separate pieces of equipment, much of it requiring skills to operate it safely.

Read MoreA global consumer goods manufacturer was experiencing high levels of downtime, jams, and long changeovers on a critical production line. They invited Process Improvement Partners to their plant to observe and discuss the problem and identify opportunities for improvement. After reviewing performance, we took a walk to the line. The line was running, and after a description of line components, it became apparent there were quick opportunities to improve performance of the line.

Read More

I was Lean Champion for the global technology team at Armstrong World Industries for many years. During that time, I supported teams of technicians, scientists, engineers, project managers, and the leadership team across four different departments. I had the good fortune to assist teams in their efforts to develop and launch new products, deploy capital equipment, and build factories all over the world. All departments had access to the Pilot Plant to support their efforts when necessary.

Read MoreIn 2011, I was asked to facilitate a Kaizen in Pensacola Florida. The problem to be solved was to improve material flow through the plant. Specifically, there were millions of square feet of goods in process, and items were getting lost, damaged, and generally causing confusion and chaos in the plant.

Read MoreWe have been taught that Red means stop and Green means go. In the context of Process Improvement, Red means that something isn’t performing as expected, and Green means everything is OK. But is it?

Read More