How clarity, respect, and one simple agreement unlocked engagement and protected results.

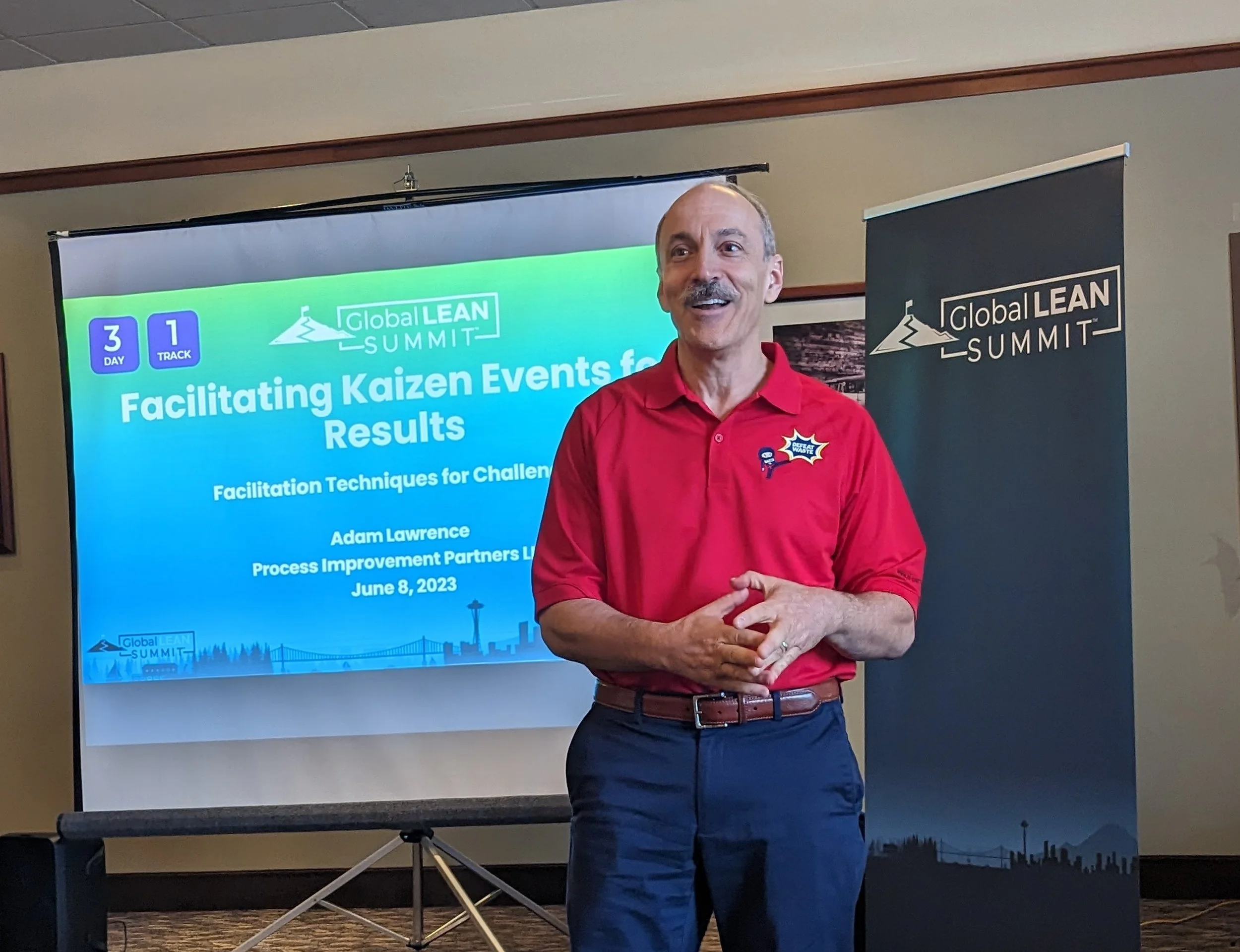

Read MoreHow years of consistent Kaizen work turned into unexpected recognition and new opportunity.

Read MoreHow one frustrated engineer reshaped the way I prepare leaders for successful Kaizen.

Read MoreHow a tough day on the plant floor reshaped my understanding of leadership, focus, and trust.

Read MoreThe early lesson that reshaped how I scope, support, and design Kaizen events.

Read MoreHow visible discipline and consistency helped reset culture in a struggling manufacturing plant.

Read MoreWhat a four-day asbestos audit taught me about discipline, resilience, and what safety really means.

Read MoreWhy stepping outside your comfort zone can open doors you never expected.

Read MoreThe research and development team created a product that they thought would change the ceiling grid market. The bad news is that it was hard to produce and no one bought it. The good news is that it lead to future innovations that the market loved.

Read MoreDuring our benchmarking tour of our European plants, we met hourly operators who were so engaged in their work that they had process understanding that rivaled one of our highest level scientists. And, they wanted to know more!

Read MoreKaizen is messy. It should be so accessible that anyone can do it. So, I use a phrase that I was taught many years ago, to make it okay to try and fail and learn quickly. The phrase? Butt Ugly by Friday!

Read More