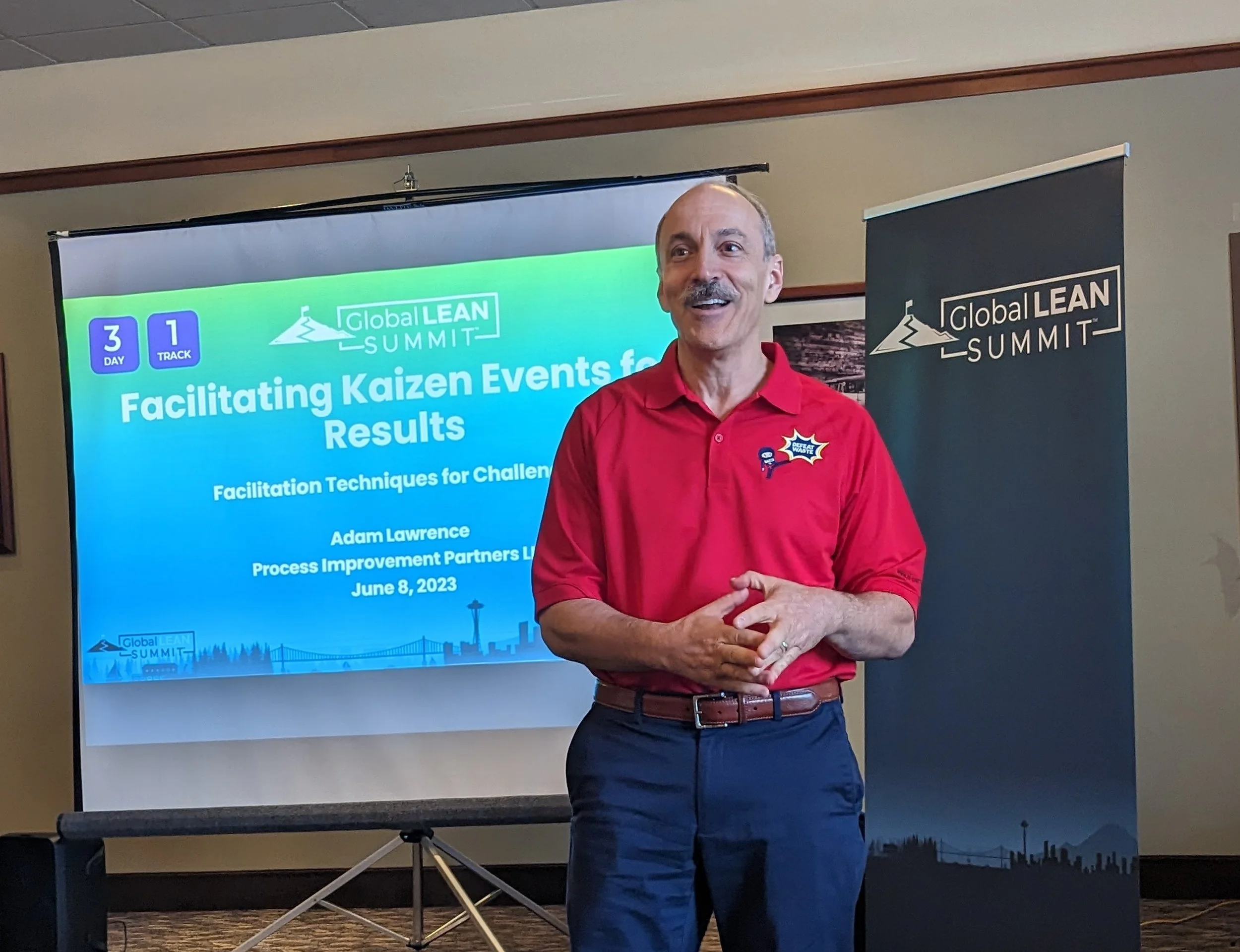

How one frustrated engineer reshaped the way I prepare leaders for successful Kaizen.

Read MoreHow a tough day on the plant floor reshaped my understanding of leadership, focus, and trust.

Read MoreHow asking a better question and slowing things down unlocked a stubborn reliability problem.

Read MoreThe early lesson that reshaped how I scope, support, and design Kaizen events.

Read MoreWhat a four-day asbestos audit taught me about discipline, resilience, and what safety really means.

Read MoreWhy stepping outside your comfort zone can open doors you never expected.

Read MoreThe research and development team created a product that they thought would change the ceiling grid market. The bad news is that it was hard to produce and no one bought it. The good news is that it lead to future innovations that the market loved.

Read MoreAs a Kaizen Ninja, I like to believe I can help any team solve any problem. Maybe I can, maybe I can’t—but believing it was causing me to dilute my message to my target audience. Let’s face it: no one believes you can be all things to all people.

Read MoreProblems are everywhere. It’s easy to feel overwhelmed and give up, thinking there are more problems than solutions. While it’s true we can’t solve everything—and some things are simply out of our control—my advice is to focus on the problems you can solve and be willing to experiment until you get the results you’re looking for.

Read MoreI’ve always been a storyteller. Some people enjoy my stories, while others wish I’d get to the point faster. I get it—my approach isn’t for everyone. But storytelling is how I communicate my ideas. Sometimes, it even helps me get my way or stumble into an interesting adventure. Here’s one of those adventures.

Read MoreArmstrong World Industries has a strong safety culture and is relentless in driving to zero injuries globally. Early on in the journey to zero, our factories focused on compliance, holding people accountable to wear their safety glasses, safety shoes, and follow various protocols. That took safety to a certain level, but the company performance plateaued. How could we get to the next level of leadership?

Read MoreI was promoted to business unit manager in a union facility for Armstrong World Industries. The relationship between management and the hourly employees had been strained for many years. It was so bad that on my first day on the job, there was a sign that said, “the plant will be closing in two months.” I wondered why they had so little faith in me. The shop steward told me, “Adam, even if we could trust you, we didn’t trust the person before you and won’t trust the person after you.” It was like they had given up on any form of leadership and stability.

Read MoreArmstrong World Industries is the global leader in suspended ceilings. That might not seem like much to you, but when you sell over a billion square feet of ceiling tile and the grid to suspend it every year, you’re making a big impact in the construction and housing market.

Read MoreFor part of my career, I worked for Dal-Tile in Dallas Texas. I was the environmental, safety, health, and mining liaison for our twelve manufacturing plants. My job was to help each plant stay compliant and safe, providing training and reporting support. We had a number of factories in Texas, and I visited each one and get to the know the employees and leadership. That way, I could develop a support plan that was mutually beneficial.

Read MoreA leading global building products company reached out for assistance with a strategy session. When I spoke with Vince, the sponsor/team leader, I listened to his pain points and suggested facilitating a Value Stream Mapping (VSM) session for his team. He told me VSM wasn’t how he wanted to proceed. Even though I thought it would be the best approach, I listened to his concerns and modified my approach for his needs. I’m glad I did.

Read MoreIn my early corporate days at Thomasville Furniture, I was given the opportunity to try many things to improve the performance and quality of the operation. This story isn’t about me, but another engineer, who came up with something so creative, he saved the company millions of dollars and improved quality of the product for our customers.

Read More