How asking a better question and slowing things down unlocked a stubborn reliability problem.

Read MoreThe research and development team created a product that they thought would change the ceiling grid market. The bad news is that it was hard to produce and no one bought it. The good news is that it lead to future innovations that the market loved.

Read MoreI was in Florida, working with a residential building products manufacturer on our second Kaizen event together. This time, we focused on improving materials delivery to the production lines. The tasks were challenging, physically demanding, and slow, leading to high turnover in the material handling position.

Read MoreProblems are everywhere. It’s easy to feel overwhelmed and give up, thinking there are more problems than solutions. While it’s true we can’t solve everything—and some things are simply out of our control—my advice is to focus on the problems you can solve and be willing to experiment until you get the results you’re looking for.

Read MoreI’ve always been a storyteller. Some people enjoy my stories, while others wish I’d get to the point faster. I get it—my approach isn’t for everyone. But storytelling is how I communicate my ideas. Sometimes, it even helps me get my way or stumble into an interesting adventure. Here’s one of those adventures.

Read MoreArmstrong World Industries is the global leader in suspended ceilings. That might not seem like much to you, but when you sell over a billion square feet of ceiling tile and the grid to suspend it every year, you’re making a big impact in the construction and housing market.

Read MoreA leading global building products company reached out for assistance with a strategy session. When I spoke with Vince, the sponsor/team leader, I listened to his pain points and suggested facilitating a Value Stream Mapping (VSM) session for his team. He told me VSM wasn’t how he wanted to proceed. Even though I thought it would be the best approach, I listened to his concerns and modified my approach for his needs. I’m glad I did.

Read MoreIn my early corporate days at Thomasville Furniture, I was given the opportunity to try many things to improve the performance and quality of the operation. This story isn’t about me, but another engineer, who came up with something so creative, he saved the company millions of dollars and improved quality of the product for our customers.

Read MoreIt was my first Kaizen event with a new client in Florida. They make building products for the residential market. On my first visit with Brian, my sponsor, I saw many opportunities to apply Kaizen to and made my recommendations. He picked his current pain point, which was labor utilization at the end point of a multi-line operation. The goal of the Kaizen event would be to balance work across all lines and require less labor to support the operation. The people wouldn’t be sent home, they would be redeployed to other parts of the plant where overtime was being used to keep things running.

Read MoreI applied Lean thinking exclusively to manufacturing processes for many years of my career. I wasn’t able to stretch my thinking beyond what I could see – the production of a physical product and how it impacts the customer, business, and employees. I conducted Value Stream Mapping (VSM – a strategic planning approach based on the view of the customer) sessions for many manufacturing facilities and we were able to identify countless opportunities to significantly improve safety, productivity, quality, and customer service. I developed a reputation for my ability to engage teams and facilitate complex sessions.

Read MoreAmstrong World Industries and Worthington Steel combined forces to create the number one ceiling grid manufacturer in the world. It didn’t start out that way, as employees of both companies were feeling their way through the combination of cultures.

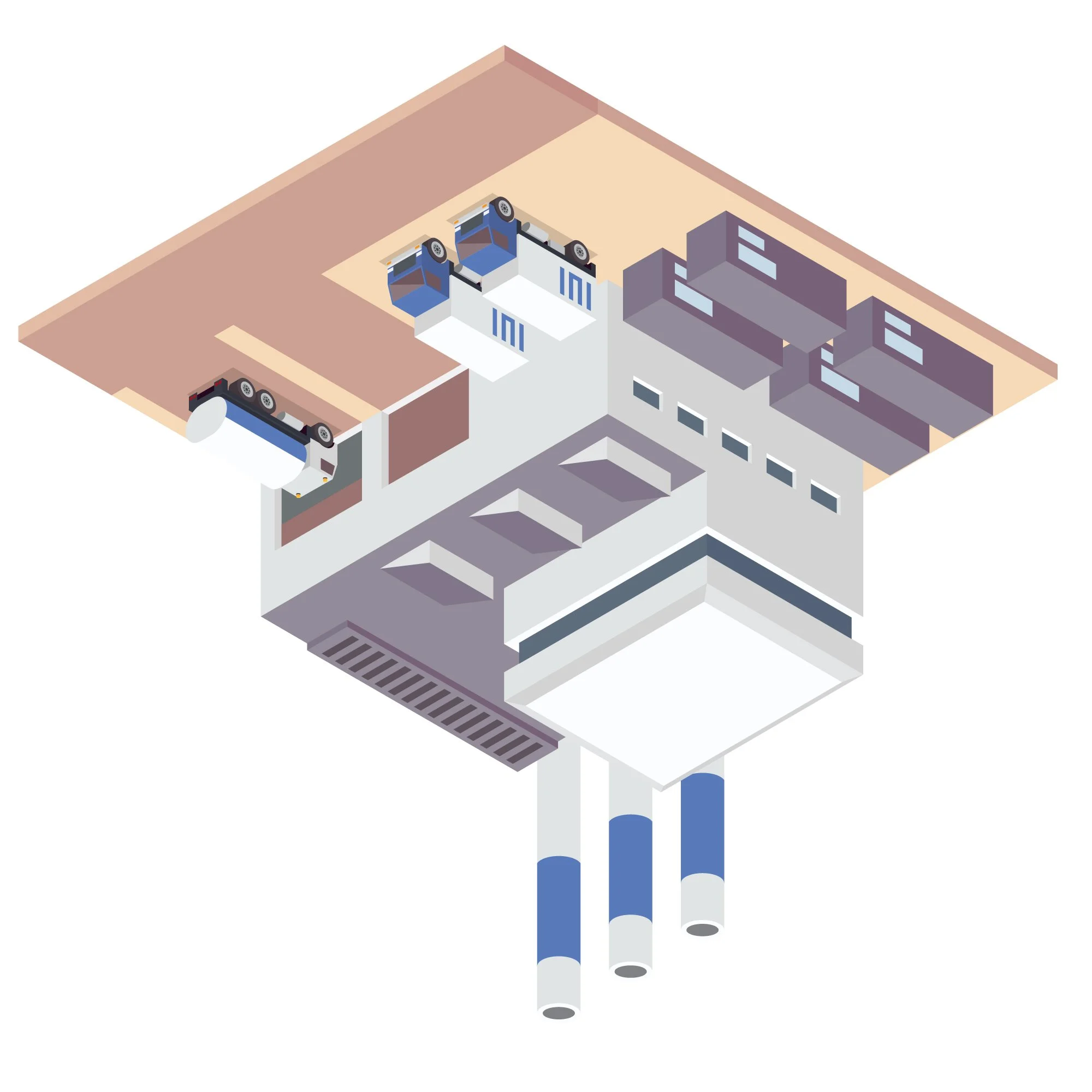

Read MoreArmstrong World Industries was forced to open a mineral wool plant, in response to the loss of a critical supplier of this vital raw material for ceiling tile manufacture. Because of this, they relied on more outside vendors to design and build the plant than they were comfortable with. They had never spun molten stone (slag) into fibers before and therefore couldn’t use their experience to reduce the potential for errors and inefficiencies in their process.

Read MoreI was asked to co-facilitate a regional cost-reduction session with my Armstrong mentor, Fred, in Europe. He had facilitated many of these sessions over the years with great success. I was excited for the opportunity to work with him and tour around countries I wasn’t familiar with.

Read MoreI developed a Kaizen facilitator training program for CITY Furniture. Once I realized I could train others in facilitation techniques I had developed over many years of experience, I decided to share the program with my network.

Read MoreEarlier this year, I received an email from someone I never met, asking about my approach to 5S – organizing a workspace to improve safety and productivity. He heard about me from another location in his company, who I helped six months earlier. Later that week, we were in a Zoom meeting, and he invited me to his factory in Oregon to see if I could help jump-start their 5S efforts.

Read MoreI love giving out little trinkets. It’s fun to see people’s reactions to the things I hand out – coins, ninjas, books. This story is about ninjas.

Read MoreCritical problems seem to happen over a holiday weekend when there is less coverage. For me, Thanksgiving provided many challenges. Early in my career, I had to come into the ceramic tile factory the day after Thanksgiving to supervise a crew trying to clear a jam in the kiln. Many years later, a water main in St. Helens Oregon broke and shut down the ceiling tile plant. Once again, I was the one covering, and had to respond quickly and deal with a near disaster.

Read More