During our benchmarking tour of our European plants, we met hourly operators who were so engaged in their work that they had process understanding that rivaled one of our highest level scientists. And, they wanted to know more!

Read MoreI took a site visit to a new client that runs a paper mill in Oklahoma. After a solid day of meeting the leadership team and touring the site, we agreed on a series of Kaizen events, starting with two 5S events, one on the paper mill side of the plant, and the other one on the converting side. Talk about night and day! In Part I, we saw what happens when the area owner wasn’t aligned. This story is about an aligned area owner.

Read MoreI took a site visit to a new client that runs a paper mill in Oklahoma. After a full day of meeting the leadership team and touring the factory, we agreed to a series of Kaizen events, starting with two 5S events, one in the paper mill building, and the other one in the converting building. Talk about night and day! Here’s the first story about what happens when the area owner wasn’t aligned. (And to learn about the experience when the area owner is aligned, be sure to read Part II.)

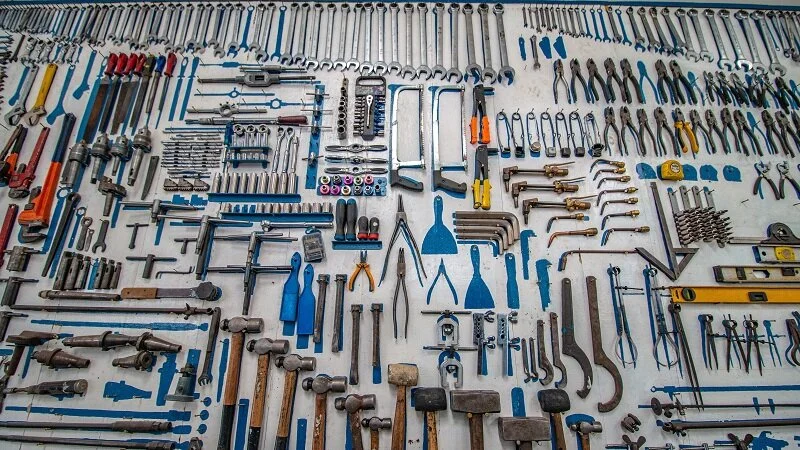

Read MoreI’m always organizing things around the house. One winter, I cut the shapes of my tools into foam and lined the drawers of my tool box. It looked so nice, I showed it to my family so they could admire it too. They humored me, but didn’t seem very impressed.

On a trip to Costco, I bought a labeler. It seemed like something that might come in handy for one of my home organization projects. Peggy, my wife, asked me what I needed with one. I wasn’t sure, but it was inexpensive. What was the harm in having one?

Read MoreI visited a consumer goods factory in Pennsylvania. They were profitable, but concerned their ability to service customer orders was deteriorating. I met with plant leadership and took a Gemba walk through the distribution center.

Read MoreThe Pilot Plant at Armstrong World Industries, a global ceiling tile manufacturer, has tons of operating equipment designed to allow technicians, engineers, and scientists to try out their ideas and experiment in their efforts to create new processes and products. One of the areas in the Pilot Plant that gets the most use is the wood shop. Containing over 50 separate pieces of equipment, much of it requiring skills to operate it safely.

Read MoreA global consumer goods manufacturer was experiencing high levels of downtime, jams, and long changeovers on a critical production line. They invited Process Improvement Partners to their plant to observe and discuss the problem and identify opportunities for improvement. After reviewing performance, we took a walk to the line. The line was running, and after a description of line components, it became apparent there were quick opportunities to improve performance of the line.

Read More

I was Lean Champion for the global technology team at Armstrong World Industries for many years. During that time, I supported teams of technicians, scientists, engineers, project managers, and the leadership team across four different departments. I had the good fortune to assist teams in their efforts to develop and launch new products, deploy capital equipment, and build factories all over the world. All departments had access to the Pilot Plant to support their efforts when necessary.

Read MoreI worked more than 30 years for a multi-national company. During that time, I had the opportunity to help teams and solve problems all over the world, from the US to Europe to Asia. I worked in five distinct industries and had many roles, from engineering to operations to continuous improvement. I enjoyed most of what I did, but realized something was missing.

Read MoreIn 2011, I was asked to facilitate a Kaizen in Pensacola Florida. The problem to be solved was to improve material flow through the plant. Specifically, there were millions of square feet of goods in process, and items were getting lost, damaged, and generally causing confusion and chaos in the plant.

Read MoreIn 2010, the company I used to work for decided to go Lean. They brought in consultants, who taught tools and techniques to employees all over the world. One tool I learned from them was 3P - Production Preparation Process. This technique maximizes creativity of a team by driving their thinking way beyond their comfort level.

Read More