How years of consistent Kaizen work turned into unexpected recognition and new opportunity.

Read MoreHow one frustrated engineer reshaped the way I prepare leaders for successful Kaizen.

Read MoreThe early lesson that reshaped how I scope, support, and design Kaizen events.

Read MoreWhy stepping outside your comfort zone can open doors you never expected.

Read MoreKaizen is messy. It should be so accessible that anyone can do it. So, I use a phrase that I was taught many years ago, to make it okay to try and fail and learn quickly. The phrase? Butt Ugly by Friday!

Read MoreI used to think customer acquisition was the most difficult and challenging aspect of my business. Once I realized customer retention is top priority, it changed my perspective and approach.

Read MoreKaizen events can be life-changing for team members. This is the story of Steve, who grew so much during the week that his co-workers almost didn’t recognize him.

Read MoreAfter many years, I was able to influence my number one client to take their Gemba walk to the next level of performance. When the hourly production operator stood up and gave his perspective, it changed the mind set of the leadership team.

Read MoreI often meet people who are interested in the work I do, and sometimes, these conversations turn into future business opportunities. One statement I hear quite frequently goes something like this: “I see you’ve made great strides working with manufacturers in [insert industry here]. But we’re different, so I want to know what experience you have in my industry.”

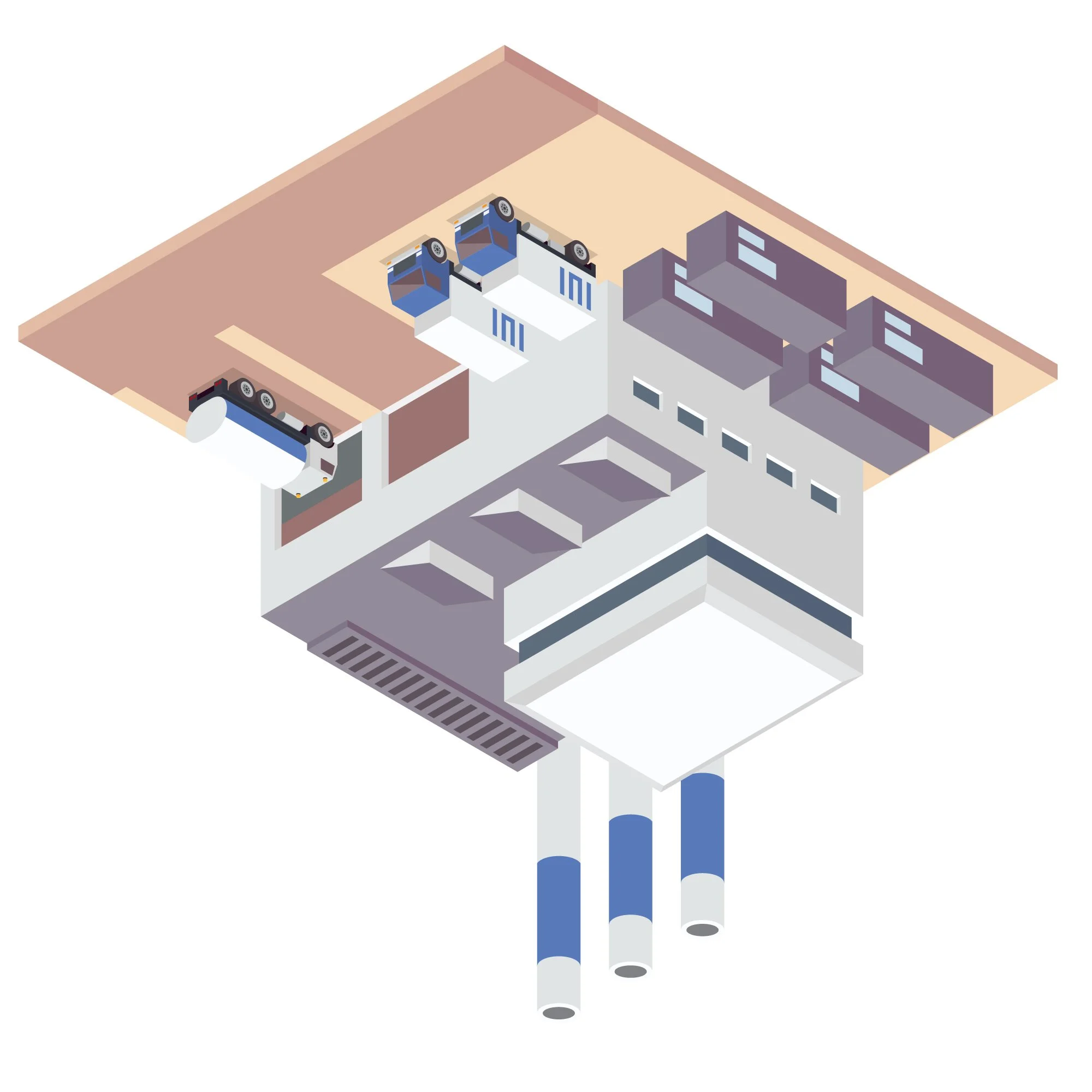

Read MoreI’m passionate about helping teams improve the reliability of their processes, using basic yet effective techniques to immediately boost the performance of their manufacturing lines. The best part is that the team can see and feel the results, and the techniques I teach are easy to learn and transferable to other lines and processes within the facility.

Read MoreI was in Florida, working with a residential building products manufacturer on our second Kaizen event together. This time, we focused on improving materials delivery to the production lines. The tasks were challenging, physically demanding, and slow, leading to high turnover in the material handling position.

Read MoreAs a Kaizen Ninja, I like to believe I can help any team solve any problem. Maybe I can, maybe I can’t—but believing it was causing me to dilute my message to my target audience. Let’s face it: no one believes you can be all things to all people.

Read MoreMany of my early projects for Armstrong World Industries were at the Macon Georgia plant. This was and still is the largest ceiling plant in the world, with a capacity of over half a billion square feet of ceiling tiles produced annually.

Read MoreSometimes, even though you know you could help a prospect, they don’t feel the same way. This is one of those stories about my inability to create alignment with a business leader.

Read MoreWhen I opened my business, I tried many ways to attract clients. After spending money on advertising that didn’t lead to business, I focused on delivering a great customer experience and then let my business grow organically through word of mouth and referrals. This is a slower path, but it fits my principles of how I want to conduct my business.

Read MoreOn May 15, 2018, I registered Process Improvement Partners LLC as an official business. Since then, I have had so many adventures, made lots of mistakes, and hopefully learned from many of them!

Read More