I used to think customer acquisition was the most difficult and challenging aspect of my business. Once I realized customer retention is top priority, it changed my perspective and approach.

Read MoreRight before the pandemic, I was asked to conduct a site assessment by one of my clients. The twist here is that it wasn’t for one of their own plants. Rather, they wanted me to assist one of their key suppliers, who was a co-packer (someone who packages and labels products for its clients and sometimes manufactures products using the clients’ brand). I should have seen the warning signs sooner.

Read MoreDuring my time living on the west coast, I wanted to give back to the community. Many of the staff at the St. Helens, Oregon plant participated in some way or another with the United Way of Columbia County. I was intrigued. I had participated in many United Way Days of Caring during my time in Pennsylvania.

Read MoreDo all your meetings happen in a room? Mine did, until I realized we needed to do something to shock the system and change our performance quickly.

I was the Business Unit Manager at Armstrong’s vinyl flooring plant in Pennsylvania. Our performance and profitability had been in a downward spiral for many years prior to my arrival and things weren’t getting any better while I was in charge.

Read MoreI was the Production Manager at the St. Helens Ceiling Tile plant for just under three years. I had always wanted to apply my continuous improvement mindset to a production organization. The VP of Manufacturing gave me a chance and I was determined to repay his trust and support with excellent results.

Read MoreDuring a virtual Lean summit, I met the CEO of a large furniture retailer from Florida. He had implemented Lean in his business for 15 years and was reaping the rewards of it. During our conversation, we talked about Kaizen events. He regretted his company had stopped conducting them a few years earlier and missed the energy, excitement, and engagement they created.

Read MoreI was the quality control manager for a ceiling grid factory in Maryland. In my first days at the plant, I observed that quality performance was minimally acceptable. There was a lot of room for improvement. I learned from my prior experience as a supervisor in Chicago to involve more people in the process and give them the information they needed to make proper quality decisions.

Read MoreIf you produce a physical product, it’s easy to see things being created. You can count them, measure them, and identify the cost to produce them. But what happens when you create knowledge or a new product idea. How do you measure your output? More importantly, how do you measure your effectiveness and identify when you need help?

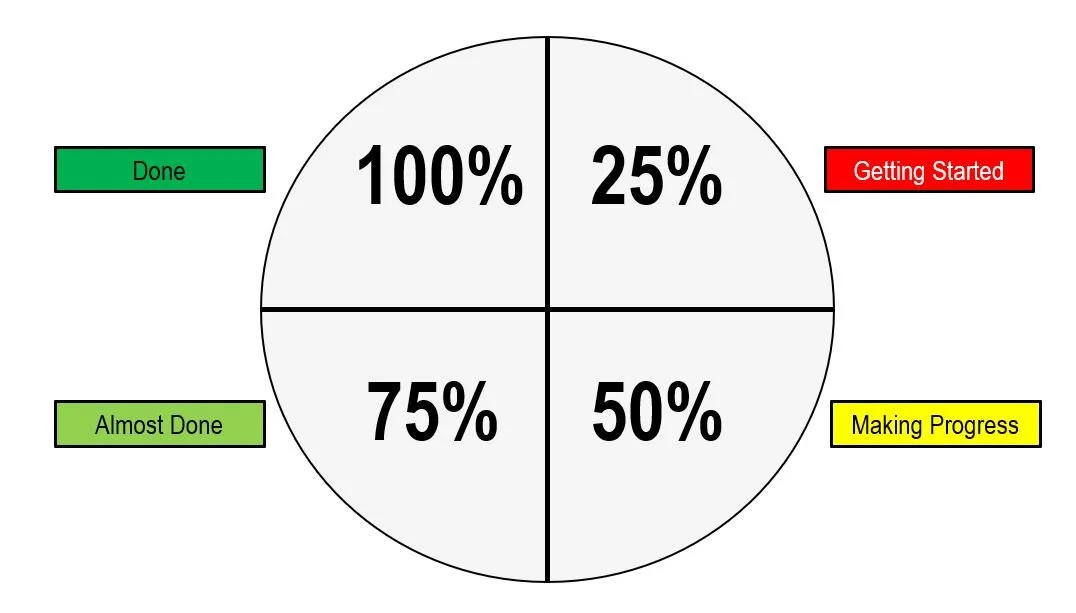

Read MoreDuring a Kaizen event, teams identify projects to work on and then go off and do the work, hoping to return with a finished product. In my early experience, I allowed team members to work on their own. I hoped they would complete their work in a reasonable amount of time. It didn’t always turn out that way. Hope is not a plan.

Read MoreA global consumer goods manufacturer was experiencing high levels of downtime, jams, and long changeovers on a critical production line. They invited Process Improvement Partners to their plant to observe and discuss the problem and identify opportunities for improvement. After reviewing performance, we took a walk to the line. The line was running, and after a description of line components, it became apparent there were quick opportunities to improve performance of the line. The techniques we would use were quite basic: leveling, squaring, aligning, and centering of products with the process. It seemed so simple, and the customers were skeptical. We suggested a five-day Kaizen to improve line reliability, scheduled for January 2019.

Read More