I was in Florida, working with a residential building products manufacturer on our second Kaizen event together. This time, we focused on improving materials delivery to the production lines. The tasks were challenging, physically demanding, and slow, leading to high turnover in the material handling position.

Read MoreAs a Kaizen Ninja, I like to believe I can help any team solve any problem. Maybe I can, maybe I can’t—but believing it was causing me to dilute my message to my target audience. Let’s face it: no one believes you can be all things to all people.

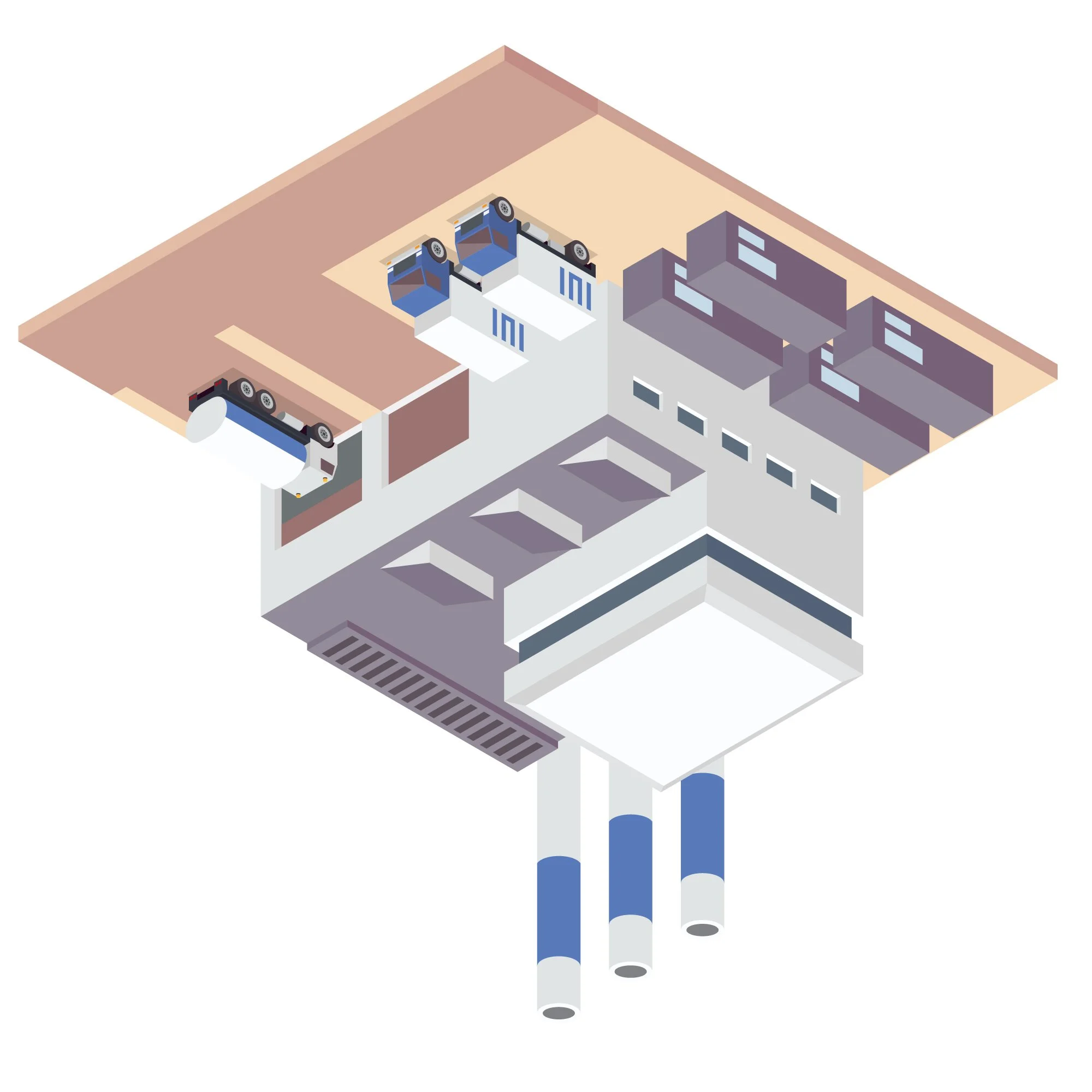

Read MoreArmstrong World Industries was forced to open a mineral wool plant, in response to the loss of a critical supplier of this vital raw material for ceiling tile manufacture. Because of this, they relied on more outside vendors to design and build the plant than they were comfortable with. They had never spun molten stone (slag) into fibers before and therefore couldn’t use their experience to reduce the potential for errors and inefficiencies in their process.

Read MoreAfter a three-year stint as Operations Manager in a plant in Oregon, I was offered the opportunity to return to the Innovation Group in the global technology group for Armstrong World Industries, a ceiling tile manufacturer. I was to support a group of scientists, technicians, and innovators improve their processes and speed up the time to launch new product ideas.

Read MoreAs a young engineer at Thomasville Furniture, I was given project assignments at the discretion of my manager. He gave me ample opportunities to try out different ideas and supported my efforts. I spent many hours in our manufacturing facilities and was fascinated by the complexity of the manufacturing processes. Many of these processes were extremely labor-intensive and required great skill to accomplish. One such task was the assembly of the base frames of case goods, such as night stands, dressers, and other cabinet style products. These frames were the support structure of the furniture and had to be strong and sturdy to hold up to the years of abuse that furniture sees in its lifetime.

Read More