I was promoted to business unit manager in a union facility for Armstrong World Industries. The relationship between management and the hourly employees had been strained for many years. It was so bad that on my first day on the job, there was a sign that said, “the plant will be closing in two months.” I wondered why they had so little faith in me. The shop steward told me, “Adam, even if we could trust you, we didn’t trust the person before you and won’t trust the person after you.” It was like they had given up on any form of leadership and stability.

Read MoreMidway through my corporate career, I was a senior industrial engineer at Armstrong World Industries. I spent most of my time providing support to our many manufacturing facilities all over the world. I have always been fascinated by manufacturing and it never ceases to amaze me how good (and bad) decisions can immediately impact performance.

Read MoreDuring my career, I have been fortunate to have worked all over the world. I was brought up as a “tourist.” Whenever I traveled with my family, we would do everything possible to see the sights and learn the history of the region we were visiting. Because of this, I naturally enjoyed my business travel and did my best to explore and experience the culture of any location I visited.

Read MoreMy first Kaizen event with a new client in Oregon came as result of my site visit the month before. We were going to apply 5S to an area of their plant that was well behind budget. During my visit, I noticed that although prior efforts had been made to improve organization, they hadn’t stuck. With the appropriate use of Lean principles and the Wheel of Sustainability, I felt I could help them get back on track.

Read MoreBefore I developed the Wheel of Sustainability, I had to find other methods to sustain the gains my teams worked so hard to develop during weeklong events. Here’s a story of the extreme lengths one team went to make sure no one could ever make a change to their improvements.

Read MoreI was the industrial engineering manager at a ceramic tile plant in New York. We made mosaic tiles. The color went all the way through the tile. Mosaic is also a word used to describe the artistic patterns we made as special orders from our customers.

Read MoreI was the plant operations manager at Armstrong’s St. Helens, Oregon ceiling tile plant for three years. During my tenure, I was able to test and refine my management and continuous improvement approach on an operation that employed just under 100 people. I made many mistakes and I’d like to think I learned from each one of them. Sometimes, it took me a few times to learn from the same mistake.

Read MoreHere’s a mining story from my time at Dal-Tile that involves blowing up a hill!

Read MoreI’m an engineer. Please don’t hold that against me. I’d like to believe I think logically, solving problems in a scientific way. I was taught this way as I was growing up. I assumed everyone else thinks this way. How wrong I was!

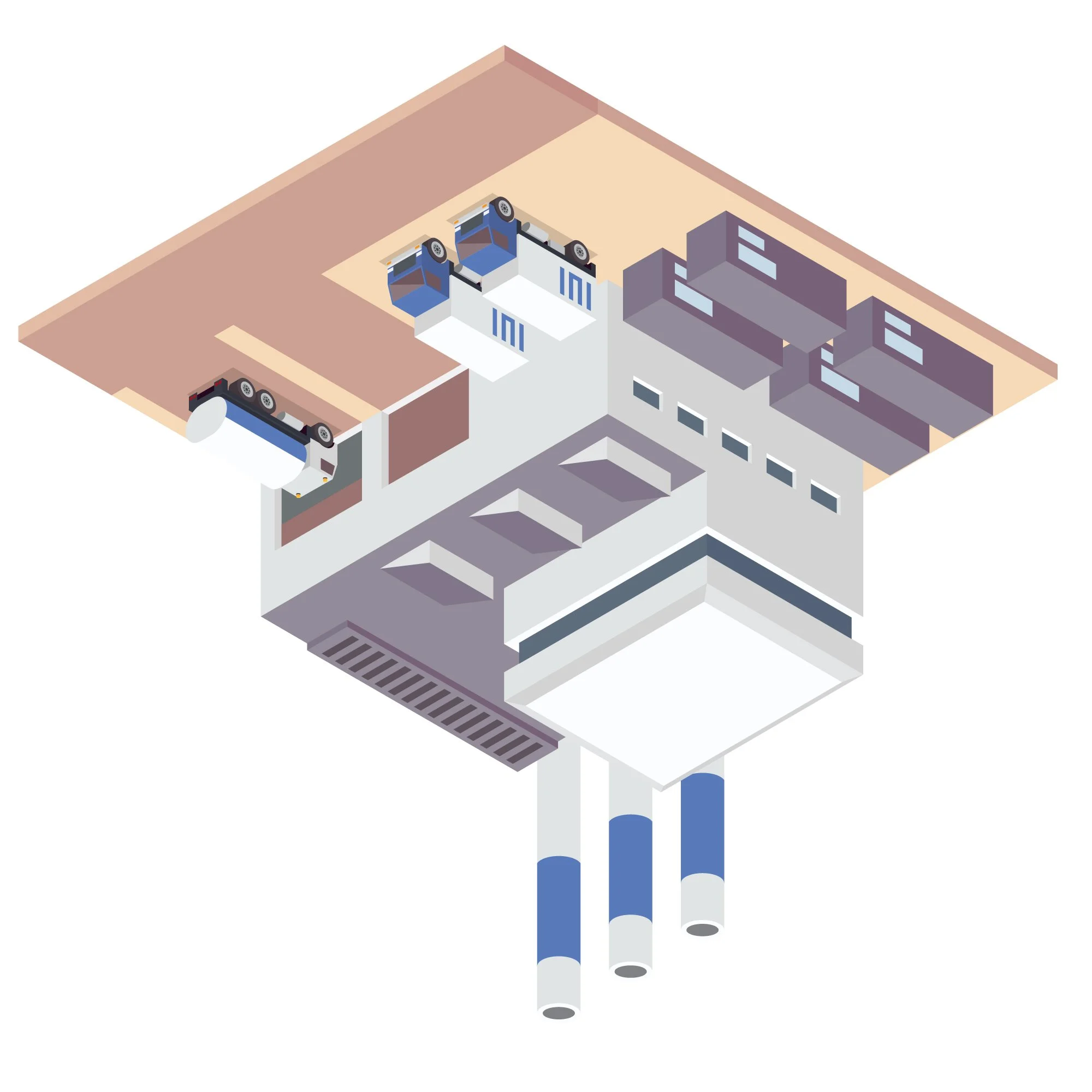

Read MoreMy first supervisory assignment was at a ceiling grid factory in Franklin Park Illinois. We had eleven operating lines at one end of the plant and a distribution center at the other end. It wasn’t unusual to produce grid in the morning and ship it out the same day. Sometimes, due to inefficiencies, we produced finished goods for customers whose trucks were waiting to be loaded on our shipping docks.

Read MoreI was working with a team in New Jersey to implement Training Within Industry (TWI) on a critical household cleaner line. Plant leadership saw this as a key element in their strategy to improve overall line performance.

Read MoreTraining and Review is the second spoke on the Wheel of Sustainability. The basis for Training and Review is Training Within Industry, which was developed at the onset of World War II to quickly train inexperienced workers to produce all the necessary armaments and supplies in support of the war effort. It’s one of the reasons the US and its allies won the war.

Read MoreWe were building a ceiling tile manufacturing plant in Russia. Like most projects, the engineering team was directed to save money, as long as it didn’t negatively impact safety or productivity. As most were unfamiliar with doing business in Russia, they used their experience with known vendors to acquire equipment for the plant. If there wasn’t enough capacity to fill equipment needs, the project team worked with local consultants to identify the “best” options for equipment purchases.

Read MoreDuring my tenure as Production Manager at a ceiling tile plant in Oregon, I implemented strict rules around changeovers: No one is allowed in the breakroom during a changeover without Team Manager approval; Everyone is available to help during the changeover; Everyone is at their stations when the line is ready to start up; One Best Way changeover procedures are followed to the letter. No deviations. The procedures were developed by the technicians. There was no reason not to follow them.

Read MoreI reported to the Vice President of Global Technology for a ceiling tile company as Lean Champion. During my tenure, we kicked off our Lean transformation and established four Value Streams: Innovation (R&D), New Product Development, Capital Engineering, and Business and Operations Support. Each Value Stream Director guided efforts to deliver value to the internal and external customers who relied on their critical results.

Read More