I’m an engineer. Please don’t hold that against me. I’d like to believe I think logically, solving problems in a scientific way. I was taught this way as I was growing up. I assumed everyone else thinks this way. How wrong I was!

Read MoreMy first supervisory assignment was at a ceiling grid factory in Franklin Park Illinois. We had eleven operating lines at one end of the plant and a distribution center at the other end. It wasn’t unusual to produce grid in the morning and ship it out the same day. Sometimes, due to inefficiencies, we produced finished goods for customers whose trucks were waiting to be loaded on our shipping docks.

Read MoreEarly in my career, I worked at Thomasville Furniture. I supported the veneering operations. We were building a new plant for the plywood pressing operations. I was asked to design and purchase a storage system for the heavy wood blocks that were used to create shaped plywood in a special press.

Read MoreRecognition is a key element in the Wheel of Sustainability. It refers to the telling of stories to lock in commitment to a critical change. Once someone tells a story as if they were there, it’s an indication of their commitment to the change. Recognition happens in many places. Sometimes it’s in a business setting, other times it’s personal. This is a story of personal Recognition.

Read MoreI’m always organizing things around the house. One winter, I cut the shapes of my tools into foam and lined the drawers of my tool box. It looked so nice, I showed it to my family so they could admire it too. They humored me, but didn’t seem very impressed.

On a trip to Costco, I bought a labeler. It seemed like something that might come in handy for one of my home organization projects. Peggy, my wife, asked me what I needed with one. I wasn’t sure, but it was inexpensive. What was the harm in having one?

Read MoreI was engaged to help an electronics manufacturer improve the safety and productivity of a testing lab at their Breinigsville, PA location. The problem they were trying to solve was that it took too long from the time the equipment was received to the time the test report was delivered to the customer.

We took a Gemba walk of the lab. I knew that the lack of organization and visualization of the process were key contributors to the less than acceptable performance. George, the lab owner, had worked for the company for many years and had a system that worked for him, but others had no idea what was going on and how they could help.

Read MoreIf you produce a physical product, it’s easy to see things being created. You can count them, measure them, and identify the cost to produce them. But what happens when you create knowledge or a new product idea. How do you measure your output? More importantly, how do you measure your effectiveness and identify when you need help?

Read MoreTraining and Review is the second spoke on the Wheel of Sustainability. The basis for Training and Review is Training Within Industry, which was developed at the onset of World War II to quickly train inexperienced workers to produce all the necessary armaments and supplies in support of the war effort. It’s one of the reasons the US and its allies won the war.

Read MoreSometimes we don’t see what’s right in front of us. We just do what we do and deal with the problems that inevitably arise.

I facilitated a Kaizen event for a non-profit. Contributions were declining significantly. After taking a Gemba walk through the process, we identified the need to improve donor engagement. It was taking up to two months to acknowledge the highest value donations. No wonder donors were leaving in droves. Recognition was slow and not meaningful.

Read MoreI visited a consumer goods factory in Pennsylvania. They were profitable, but concerned their ability to service customer orders was deteriorating. I met with plant leadership and took a Gemba walk through the distribution center.

Read MoreThe Five Whys is a method that can be used to understand why a change isn’t being followed. It helps you get to the root cause of any resistance or problem you observe. If you find someone doing something in a non-standard manner, ask why until you get to their motivation for doing it differently. It may take five or more whys. It could take less. Here’s a sample conversation:

Read MoreWe were building a ceiling tile manufacturing plant in Russia. Like most projects, the engineering team was directed to save money, as long as it didn’t negatively impact safety or productivity. As most were unfamiliar with doing business in Russia, they used their experience with known vendors to acquire equipment for the plant. If there wasn’t enough capacity to fill equipment needs, the project team worked with local consultants to identify the “best” options for equipment purchases.

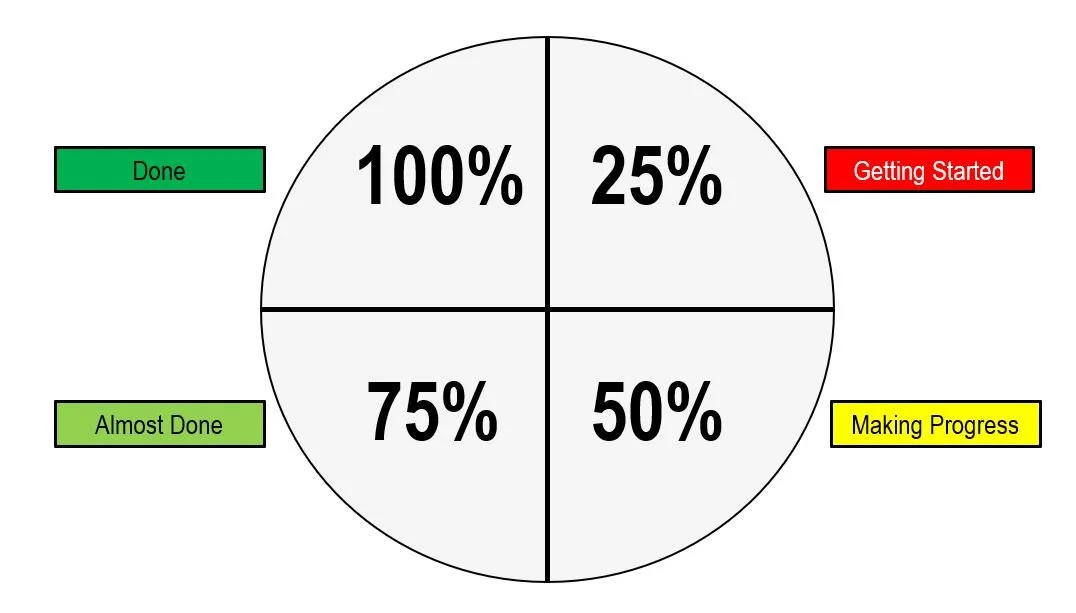

Read MoreDuring a Kaizen event, teams identify projects to work on and then go off and do the work, hoping to return with a finished product. In my early experience, I allowed team members to work on their own. I hoped they would complete their work in a reasonable amount of time. It didn’t always turn out that way. Hope is not a plan.

Read MoreIn 2007, I moved my family across country to take a new role as Production Manager for a ceiling tile plant in Oregon. The plant had a strong team-based culture. People genuinely wanted to help each other work in as safe and productive manner as possible. It wasn’t unusual to see the Plant Manager on the factory floor, assisting the technicians with their work or helping them stay safe.

Read MoreIn 2001, I was the Business Unit Manager at a Vinyl Flooring Plant in Pennsylvania. Responsible for the one of four business units on site, I had a unionized workforce of 160 employees, three supervisors, and eight technical staff. My job was to turn the shrinking business around and keep my employees safe and productive.

Read MoreDuring my tenure as Production Manager at a ceiling tile plant in Oregon, I implemented strict rules around changeovers: No one is allowed in the breakroom during a changeover without Team Manager approval; Everyone is available to help during the changeover; Everyone is at their stations when the line is ready to start up; One Best Way changeover procedures are followed to the letter. No deviations. The procedures were developed by the technicians. There was no reason not to follow them.

Read MoreAt a gummy vitamin manufacturer in Pennsylvania, I was asked to facilitate a team of mechanics responsible for supporting and maintaining the manufacturing operation. They had difficulty keeping their maintenance area compliant with strict food production regulations. Our goal was to develop a system to guarantee compliance, while improving their ability to service their customers.

Read MoreOf all the Kaizen events I have facilitated, there is nothing like 3P. It’s the most exciting, energizing, and exhausting way to create breakthroughs with a team. 3P stands for Production Preparation Process. The idea is to design a new product or process with the least amount of waste possible.

Read MoreIn 1998, I was invited to Hoogezand, the Netherlands, to help a team make improvements to their ceiling tile production line. Little did I know it would be the longest Kaizen event in my life. I had been to the plant three months before and identified significant changeover time reduction potential. It was time to put my money where my mouth was. In advance of the trip, we identified members of the team and the need for an interpreter. I didn’t speak Dutch and still don’t. We’d have two weeks to work on the line and were to coordinate with the Production Manager any time we needed to shut the line down to work on or test the equipment.

Read MoreIn 2010, Armstrong World Industries emerged from bankruptcy. A minority stake of the company was bought by a private equity firm. This firm knew there were many improvement opportunities and brought in consultants to help create a culture of continuous improvement across the global organization. Their approach was to hold many Kaizen events on a weekly basis, exposing as many people to the principles of Lean as quickly as possible.

Read More