I was the Production Manager at the St. Helens Ceiling Tile plant for just under three years. I had always wanted to apply my continuous improvement mindset to a production organization. The VP of Manufacturing gave me a chance and I was determined to repay his trust and support with excellent results.

Read MoreI was the Industrial Engineering manager at a ceramic tile factory in western New York for two years. During that time, I participated in many improvement projects. As a member of staff, I was responsible for various administrative and plant coverage duties. One of the most critical responsibilities I had was holiday coverage for the tile firing and curing process.

Read MoreIf you produce a physical product, it’s easy to see things being created. You can count them, measure them, and identify the cost to produce them. But what happens when you create knowledge or a new product idea. How do you measure your output? More importantly, how do you measure your effectiveness and identify when you need help?

Read MoreSometimes we don’t see what’s right in front of us. We just do what we do and deal with the problems that inevitably arise.

I facilitated a Kaizen event for a non-profit. Contributions were declining significantly. After taking a Gemba walk through the process, we identified the need to improve donor engagement. It was taking up to two months to acknowledge the highest value donations. No wonder donors were leaving in droves. Recognition was slow and not meaningful.

Read MoreI visited a consumer goods factory in Pennsylvania. They were profitable, but concerned their ability to service customer orders was deteriorating. I met with plant leadership and took a Gemba walk through the distribution center.

Read MoreWe were building a ceiling tile manufacturing plant in Russia. Like most projects, the engineering team was directed to save money, as long as it didn’t negatively impact safety or productivity. As most were unfamiliar with doing business in Russia, they used their experience with known vendors to acquire equipment for the plant. If there wasn’t enough capacity to fill equipment needs, the project team worked with local consultants to identify the “best” options for equipment purchases.

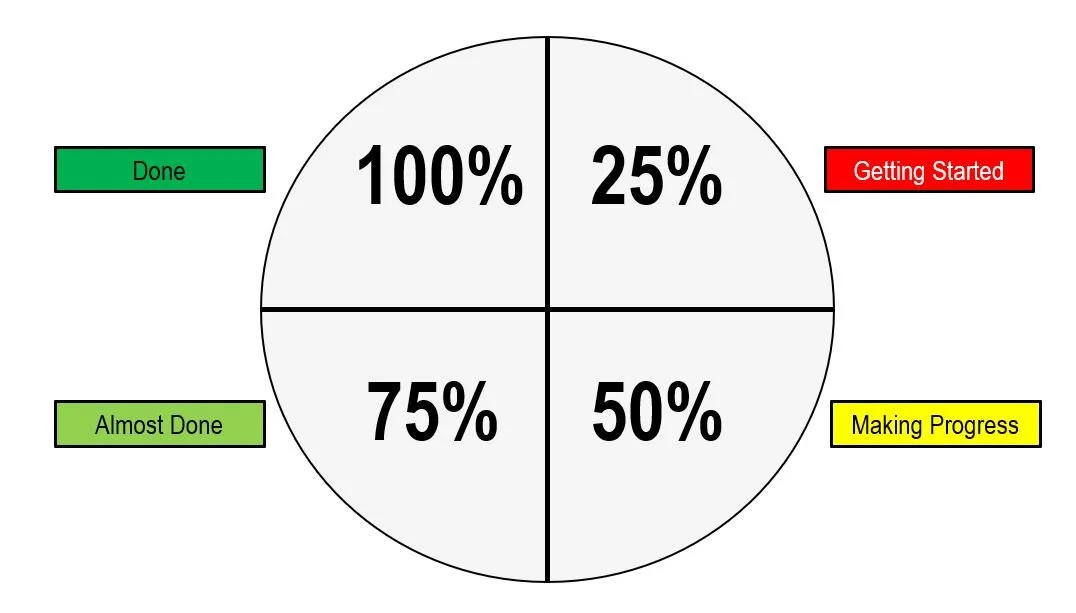

Read MoreDuring a Kaizen event, teams identify projects to work on and then go off and do the work, hoping to return with a finished product. In my early experience, I allowed team members to work on their own. I hoped they would complete their work in a reasonable amount of time. It didn’t always turn out that way. Hope is not a plan.

Read MoreDuring my corporate career, we identified a critical gap in our safety training system. There wasn’t a good way to ensure traveling engineers, scientists, and technicians were compliant for annual safety training requirements. We had to get everyone immediately compliant and then develop a system for annual recertification.

Read MoreDuring my tenure as Production Manager at a ceiling tile plant in Oregon, I implemented strict rules around changeovers: No one is allowed in the breakroom during a changeover without Team Manager approval; Everyone is available to help during the changeover; Everyone is at their stations when the line is ready to start up; One Best Way changeover procedures are followed to the letter. No deviations. The procedures were developed by the technicians. There was no reason not to follow them.

Read MoreIn 1998, I was invited to Hoogezand, the Netherlands, to help a team make improvements to their ceiling tile production line. Little did I know it would be the longest Kaizen event in my life. I had been to the plant three months before and identified significant changeover time reduction potential. It was time to put my money where my mouth was. In advance of the trip, we identified members of the team and the need for an interpreter. I didn’t speak Dutch and still don’t. We’d have two weeks to work on the line and were to coordinate with the Production Manager any time we needed to shut the line down to work on or test the equipment.

Read MoreIn 2005, a ceilings manufacturing plant on the West Coast was experiencing high downtime rates. I was asked to come to the plant and run a Kaizen event to identify the impact of downtime on the plant.

I was given a small team consisting of four production technicians, two mechanics, one electrician, one engineer, and one supervisor. Our mission wasn’t to solve the specific mechanical or electrical downtime problems, but rather to understand why the response to and recovery from downtime took so long. This was a new concept for the plant and for me, but we felt we were up to the challenge.

Read MoreIn 2019, I was asked to facilitate the annual Value Stream Mapping (strategic planning) event for a leading consumer brands manufacturer at their facility in Central Pennsylvania. I had facilitated their event the prior year and it was our intent to build on the prior results and drive their continuous improvement culture forward during the event.

Read MoreIn 2005, I was asked to be part of a team to help Armstrong’s Mobile Alabama ceiling tile plant improve their performance. Production output had steadily declined over the first few months of the year, and they were well behind budget. The team was tasked with identifying and implementing improvements to the operation that would drive performance back to budget for the full year. The team leader called the effort a “Full Court Press”, meaning we would not give up until we accomplished our mission.

Read MoreIn 2010, a private equity firm took a minority stake in Armstrong World Industries. They brought in many leaders at executive levels and committed to a strategy of Lean transformation. Their initial focus was manufacturing, and then when ready, they would expand efforts to the supporting organizations. From 2010 through 2012 in the manufacturing organization, emphasis was placed on Lean training and conducting hundreds of Kaizen events. In many cases, outside consultants were brought in. But, where there was experience, internal resources worked with teams and facilitated Kaizen events.

Read MoreEarly this year, Process Improvement Partners was invited to conduct a site assessment for a packaging company in western Pennsylvania. The facility was operating a new technology that wasn’t performing to expectations. They wanted to identify opportunities to improve their situation using the engagement and empowerment of their employees.

Read More

Armstrong World Industries makes billions of square feet of ceiling tiles every year, shipping to locations all around the world. Most of these tiles are white. The remainder are off-white or a few standard colors. If a customer wants non-standard colors, until recently, Armstrong used an outside vendor.

Read More

I was Lean Champion for the global technology team at Armstrong World Industries for many years. During that time, I supported teams of technicians, scientists, engineers, project managers, and the leadership team across four different departments. I had the good fortune to assist teams in their efforts to develop and launch new products, deploy capital equipment, and build factories all over the world. All departments had access to the Pilot Plant to support their efforts when necessary.

Read MoreProcess Improvement Partners was invited to help a gummy vitamin manufacturer reduce their changeover time. Walking through the process with the sponsor, we felt that we could attain a sustainable 50% reduction in time, while improving the safety of the process and engaging the team with a winning attitude.

Read MoreIn 2005, I was working in the central engineering group for Armstrong in Lancaster PA. One day, while I was sitting in my cubicle, the CEO of our division came up to me and told me that he needed my help at our newly acquired cabinet plant in Auburn Nebraska. I asked him what help I could provide. He looked at me and said, “Fix it – you’ll know what I mean when you get there.”

Read MoreSometimes we make things more complicated than they have to be. When we remove the complexity, things seem to get better. I have learned this lesson many times, but my trip to Macon Georgia proved it to me and my team.

Read More