I moved to Baltimore to be the industrial engineering and quality manager at a ceiling grid factory. We had just consolidated three plants into two, following a joint venture. Early on, changes were happening so fast that my plant manager informed his boss that he wasn’t comfortable with the direction of the new company. He offered to stay as long as necessary to bring his (yet unnamed) replacement up to speed.

Read MoreI was the plant operations manager at Armstrong’s St. Helens, Oregon ceiling tile plant for three years. During my tenure, I was able to test and refine my management and continuous improvement approach on an operation that employed just under 100 people. I made many mistakes and I’d like to think I learned from each one of them. Sometimes, it took me a few times to learn from the same mistake.

Read MoreI have been a small business owner for a few years. My company consists of me, my wife, my son, and my dog. I quickly learned I am responsible for everything that goes on. Nowhere is this more critical than customer acquisition.

Read MoreOur fiberglass ceiling tile plant in Ohio got their board stock from another company (let’s call them Vendor X). They had some problems with the quality of some of the boards they received. As Vendor X was a critical partner, they decided to co-host a Kaizen event to eliminate the quality problems.

Read MoreHere’s a mining story from my time at Dal-Tile that involves blowing up a hill!

Read MoreAfter five years as Lean Champion, my voice wasn’t being heard so well. Sure, I was able to promote and facilitate Kaizen events and help people solve problems, but I was unable to move the leadership team to take the next steps in our Lean journey. Any time I spoke to our leaders about strategy, they were too busy to consider anything that deviated from their current operating approach.

Read MoreI was working with a team in New Jersey to implement Training Within Industry (TWI) on a critical household cleaner line. Plant leadership saw this as a key element in their strategy to improve overall line performance.

Read MoreSometimes we don’t see what’s right in front of us. We just do what we do and deal with the problems that inevitably arise.

I facilitated a Kaizen event for a non-profit. Contributions were declining significantly. After taking a Gemba walk through the process, we identified the need to improve donor engagement. It was taking up to two months to acknowledge the highest value donations. No wonder donors were leaving in droves. Recognition was slow and not meaningful.

Read MoreWe were building a ceiling tile manufacturing plant in Russia. Like most projects, the engineering team was directed to save money, as long as it didn’t negatively impact safety or productivity. As most were unfamiliar with doing business in Russia, they used their experience with known vendors to acquire equipment for the plant. If there wasn’t enough capacity to fill equipment needs, the project team worked with local consultants to identify the “best” options for equipment purchases.

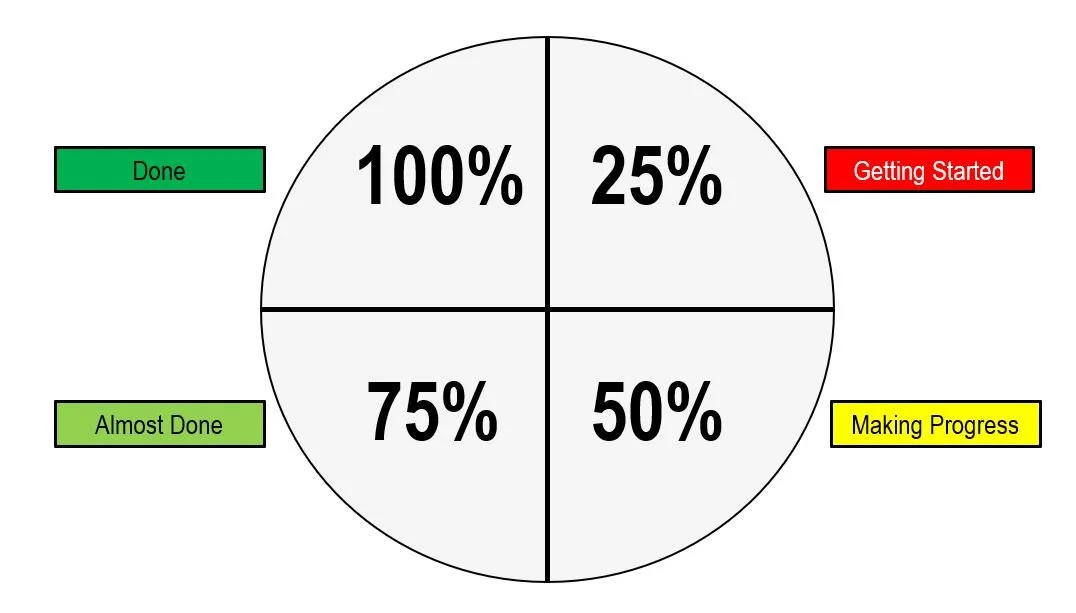

Read MoreDuring a Kaizen event, teams identify projects to work on and then go off and do the work, hoping to return with a finished product. In my early experience, I allowed team members to work on their own. I hoped they would complete their work in a reasonable amount of time. It didn’t always turn out that way. Hope is not a plan.

Read MoreDuring my corporate career, we identified a critical gap in our safety training system. There wasn’t a good way to ensure traveling engineers, scientists, and technicians were compliant for annual safety training requirements. We had to get everyone immediately compliant and then develop a system for annual recertification.

Read MoreI was Lean Champion for the Global Technology group at a ceiling tile manufacturer for six years. During that time, I was responsible to train all new employees in Lean principles and techniques as they joined our group. The goal of this training was to help them understand what we were doing and how we applied Lean to our work. My aim was to generate interest and engagement around Lean. In the early years, things didn’t always go the way I expected.

Read MoreI reported to the Vice President of Global Technology for a ceiling tile company as Lean Champion. During my tenure, we kicked off our Lean transformation and established four Value Streams: Innovation (R&D), New Product Development, Capital Engineering, and Business and Operations Support. Each Value Stream Director guided efforts to deliver value to the internal and external customers who relied on their critical results.

Read MoreIn 2011, I was asked to facilitate a changeover reduction Kaizen event at a ceiling tile plant in Florida. Most changeover reduction events have a goal of reducing time by 50%, while maintaining or improving quality and safety. In this case, the team was asked to reduce changeover time by 90%. This would be a challenge for the team and my ability to facilitate them to a solution.

Read MoreAt a gummy vitamin manufacturer in Pennsylvania, I was asked to facilitate a team of mechanics responsible for supporting and maintaining the manufacturing operation. They had difficulty keeping their maintenance area compliant with strict food production regulations. Our goal was to develop a system to guarantee compliance, while improving their ability to service their customers.

Read MoreOf all the Kaizen events I have facilitated, there is nothing like 3P. It’s the most exciting, energizing, and exhausting way to create breakthroughs with a team. 3P stands for Production Preparation Process. The idea is to design a new product or process with the least amount of waste possible.

Read MoreIn 1998, I was invited to Hoogezand, the Netherlands, to help a team make improvements to their ceiling tile production line. Little did I know it would be the longest Kaizen event in my life. I had been to the plant three months before and identified significant changeover time reduction potential. It was time to put my money where my mouth was. In advance of the trip, we identified members of the team and the need for an interpreter. I didn’t speak Dutch and still don’t. We’d have two weeks to work on the line and were to coordinate with the Production Manager any time we needed to shut the line down to work on or test the equipment.

Read MoreIn 2010, Armstrong World Industries emerged from bankruptcy. A minority stake of the company was bought by a private equity firm. This firm knew there were many improvement opportunities and brought in consultants to help create a culture of continuous improvement across the global organization. Their approach was to hold many Kaizen events on a weekly basis, exposing as many people to the principles of Lean as quickly as possible.

Read MoreFor many years, I have led, facilitated, or participated in hundreds of Kaizen events. During those events, people worked together in the same location to solve important problems. Sometimes team members travelled to the location of the event. Other times people weren’t able to travel to the event and the team carried on without identified experts. I loved the interaction and energy of those events, but wondered if there might be a way to hold an event that was as effective as putting people in the same room, but would be less difficult from a travel or logistical perspective.

Read MoreI was the Lean Champion for Armstrong World Industries for six years. My responsibility was to guide the organization to a continuous improvement mindset in all of their activities. I had no direct reports and reported to the Executive Vice President of Global Technology. When we kicked off our Lean transformation, most in the organization felt we were implementing the “flavor of the week” and weren’t ready to commit to changing their habits.

Read More