During our benchmarking tour of our European plants, we met hourly operators who were so engaged in their work that they had process understanding that rivaled one of our highest level scientists. And, they wanted to know more!

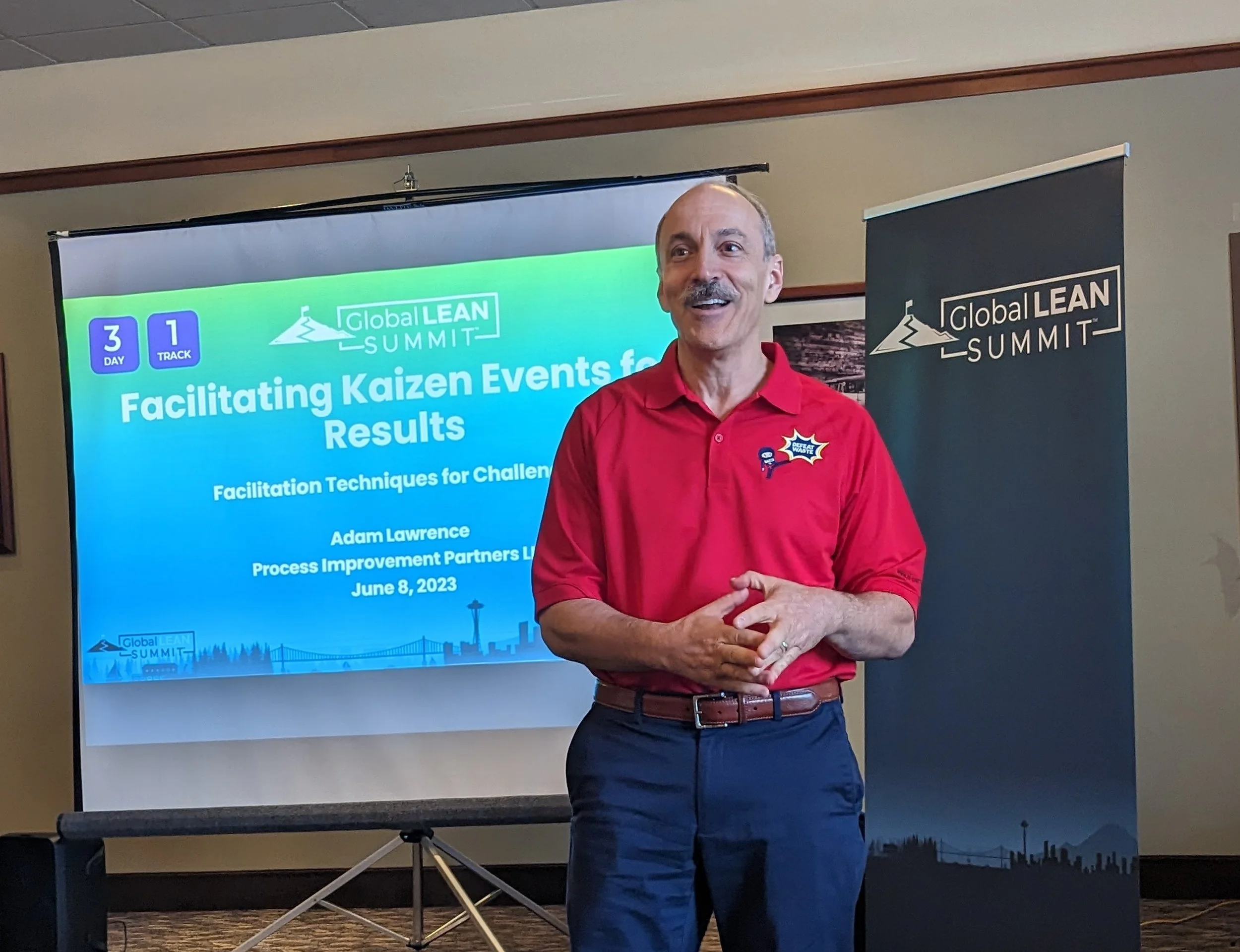

Read MoreKaizen is messy. It should be so accessible that anyone can do it. So, I use a phrase that I was taught many years ago, to make it okay to try and fail and learn quickly. The phrase? Butt Ugly by Friday!

Read MoreKaizen events can be life-changing for team members. This is the story of Steve, who grew so much during the week that his co-workers almost didn’t recognize him.

Read MoreAfter many years, I was able to influence my number one client to take their Gemba walk to the next level of performance. When the hourly production operator stood up and gave his perspective, it changed the mind set of the leadership team.

Read MoreI’m passionate about helping teams improve the reliability of their processes, using basic yet effective techniques to immediately boost the performance of their manufacturing lines. The best part is that the team can see and feel the results, and the techniques I teach are easy to learn and transferable to other lines and processes within the facility.

Read MoreI was in Florida, working with a residential building products manufacturer on our second Kaizen event together. This time, we focused on improving materials delivery to the production lines. The tasks were challenging, physically demanding, and slow, leading to high turnover in the material handling position.

Read MoreArmstrong World Industries has a strong safety culture and is relentless in driving to zero injuries globally. Early on in the journey to zero, our factories focused on compliance, holding people accountable to wear their safety glasses, safety shoes, and follow various protocols. That took safety to a certain level, but the company performance plateaued. How could we get to the next level of leadership?

Read MoreI was promoted to business unit manager in a union facility for Armstrong World Industries. The relationship between management and the hourly employees had been strained for many years. It was so bad that on my first day on the job, there was a sign that said, “the plant will be closing in two months.” I wondered why they had so little faith in me. The shop steward told me, “Adam, even if we could trust you, we didn’t trust the person before you and won’t trust the person after you.” It was like they had given up on any form of leadership and stability.

Read MoreArmstrong World Industries is the global leader in suspended ceilings. That might not seem like much to you, but when you sell over a billion square feet of ceiling tile and the grid to suspend it every year, you’re making a big impact in the construction and housing market.

Read MoreFor part of my career, I worked for Dal-Tile in Dallas Texas. I was the environmental, safety, health, and mining liaison for our twelve manufacturing plants. My job was to help each plant stay compliant and safe, providing training and reporting support. We had a number of factories in Texas, and I visited each one and get to the know the employees and leadership. That way, I could develop a support plan that was mutually beneficial.

Read MoreA leading global building products company reached out for assistance with a strategy session. When I spoke with Vince, the sponsor/team leader, I listened to his pain points and suggested facilitating a Value Stream Mapping (VSM) session for his team. He told me VSM wasn’t how he wanted to proceed. Even though I thought it would be the best approach, I listened to his concerns and modified my approach for his needs. I’m glad I did.

Read More